Schedule 40 Pvc Vs Schedule 80 Pvc, Set 40 PVC against Schedule 80. PVC sets the mood for this gripping narrative by giving readers a glimpse of a unique and thorough plot right away. The resources utilized in building and plumbing often define the sector; PVC pipes in particular have become a pillar because of their affordability, adaptability, and durability.

Other variants of the PVC pipe family, nevertheless, each meet a specific need or function. Examining their unique features, uses, and considerations, this presentation explores the basic variations between Schedule 40 and Schedule 80 PVC pipes so that one may have a complete understanding of these indispensable materials.

Between Schedule 40 and Schedule 80 PVC, factors including pressure needs, environmental conditions, and project specifications help to determine which is best. This talk will lead you through these problems so you may decide for your own project with knowledge.

By examining their physical characteristics, pressure ratings, and installation peculiarities as well as their strengths and limitations, we will determine the ideal uses for Schedule 40 and Schedule 80 PVC.

An introduction to PVC pipes.

In the construction and other sectors, PVC pipes are a flexible and usually utilized material. Their simplicity of installation, low cost, and lifespan help to explain their attraction. Usually constructed of polyvinyl chloride (PVC), a synthetic material noted for its resistance to weathering, chemicals, and corrosion, these pipes are

PVC pipes are categorized according to their “Schedule,” or pressure rating. This method sorts pipes according to wall thickness, which directly influences their capacity to maintain internal pressure. More strength and pressure resistance follow from a thicker wall indicated by a higher schedule number.

Schedule 40 vs. Schedule 80 PVC Pipes

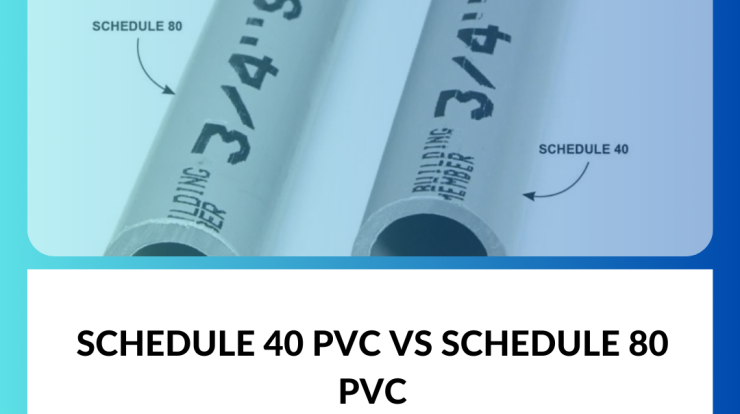

Schedule 40 and Schedule 80 PVC pipes differ fundamentally mostly in their wall thickness. Because their walls are thicker than those of Schedule 40 pipes, Schedule 80 pipes are far tougher and more pressure-resistant. Applications requiring higher pressure resistance depend critically on this range in wall thickness.

Wall Thickness and Pressure Rating

Think of this, buddy: a PVC pipe’s wall thickness determines its resistance to pressure before bursting. Like those bamboo homes in Bal Lanka.The building is more robust the thicker the bamboo is. How how thick is enough? Schedules 40 and 80 then become really useful.

Wall Thickness Comparison

The wall thickness of Schedule 40 and Schedule 80 PVC pipes defines their pressure rating directly. Thicker walls of Schedule 80 pipes than of Schedule 40 pipes define them. This is a brief analogy.

Smaller wall thickness Schedule 40 PVC pipes have than Schedule 80 PVC pipes.

Pressure Rating and Wall Thickness

The capacity of a PVC pipe to withstand internal pressure without breaking defines its pressure rating. A thicker wall suggests increased pipe pressure tolerance.

Higher pressure rating comes from a thicker wall.

Pressure Ratings for Schedule 40 and Schedule 80 PVC Pipes

The diameter of Schedule 40 and Schedule 80 PVC pipes affects their pressure rating as well as the fluid’s temperature moving through them.Typical pressure ratings for Schedule 40 and Schedule 80 PVC pipes at 73°F (23°C) are broken out here:

Applications and Considerations

Understanding their uses and the elements influencing the best choice for your project will help you decide between Schedule 40 and Schedule 80 PVC pipes. Though their particular qualities make them suitable for a range of uses, both types are quite robust and corrosion resistant.

Common Applications of Schedule 40 PVC Pipes

Because of their mix of strength and cost efficiency, schedule 40 PVC pipes find extensive use in a range of projects.

Water Distribution Systems: Schedule 40 PVC is extensively applied for potable water distribution including municipal water pipes, domestic plumbing, and irrigation systems.

Drainage and Sewer Systems: Due to its chemical resistance and durability, drainage and sewers systems find ideal fit as well as wastewater and stormwater runoff control.

Industrial Applications: Schedule 40 PVC is used in manufacturing, chemical processing, and agricultural sectors as well as other non-corrosive fluid carrying applications.

Agricultural Applications: It is extensively used in irrigation systems for farms to effectively provide water for their crops.

Vent and Exhaust Systems: Schedule 40 PVC is suitable for ventilation and exhaust systems moving gasses and air.

Common Applications of Schedule 80 PVC Pipes

Applications needing more pressure resistance and durability call for Schedule 80 PVC pipes.

High-Pressure Applications: Applications including industrial plumbing systems, compressed air lines, and fire sprinkler systems—high-pressure ones—better fit Schedule 80 PVC.

Underground Piping: Underground pipe systems that must withstand soil pressure and possible damage are appropriate for their higher strength.

Chemical Processing: Schedule 80 PVC finds extensive application in high-temperature corrosive chemical handling facilities.

Gas Distribution: Natural gas distribution systems use advantage of it to guarantee dependable and safe gas transportation.

Swimming Pool Systems: Swimming pool systems often make use of 80 PVC since it is chlorine and other chemical resistant.

Situations Where Schedule 80 PVC is Preferred

Applications calling for improved pressure resistance, strength, and safety choose Schedule 80 PVC above Schedule 40 PVC.

Working with high-pressure fluids or gasses calls for Schedule 80 PVC’s greater safety and dependability.

80 PVC is sturdy enough underground pipework to resist potential damage and soil pressure.

High-Temp Uses: Schedule 80 PVC is perfect for use involving hot fluids or gases since it is more heat-resistant than Schedule 40 PVC.

Schedule 80 PVC is routinely used in chemical processing plants to handle corrosive chemicals while preserving structural integrity.

Applications with High Loads: Schedule 80 PVC is fit for high-load uses including large-diameter piping systems because to its strengthened quality.

Factors to Consider When Choosing Between Schedule 40 and Schedule 80 PVC

Several factors guide the choice between Schedule 40 and Schedule 80 PVC, including:

Designed for high-pressure uses, Schedule 80 PVC is more pressure rated than Schedule 40 PVC.

The particular needs of the application—such as the type of fluid being transferred, temperature, and pressure—will help to define the best option.

Cost: Schedule 80 PVC is typically more costly than Schedule 40 PVC, hence price factors become quite important.

Availability: Although Schedule 80 PVC may be less commonly available in some regions, both forms of PVC pipes should be tested.

Installation Requirements: One should take into account the installation needs for both kinds of PVC pipes since Schedule 80 PVC can call for the application of particular tools or methods.

Physical Properties and Durability: Schedule 40 Pvc Vs Schedule 80 Pvc

The wall thickness of Schedule 40 and Schedule 80 PVC pipes causes differing physical characteristics and endurance. Choosing the suitable pipe for a specific use depends on an awareness of these differences.

Tensile Strength, Impact Resistance, and Chemical Resistance

Wall thickness determines PVC pipes’ tensile strength, impact resistance, and chemical resistance as well. Having thicker walls, stronger tensile strength, more impact resistance, and more chemical resistance than Schedule 40 PVC pipes, Schedule 80 PVC pipes

This qualifies Schedule 80 PVC pipes for uses demanding higher strength and lifetime.

Schedule E eighty. Applications involving high pressure, impact loads, or powerful chemicals routinely call for PVC pipes.

Temperature Impact on Performance

For temperatures between 40°F and 140°F (-40°C and 60°C, PVC pipes are usually judged suitable. Extreme temperatures, however, might affect the functioning of PVC pipes.

Low temperatures could make PVC fragile and easily broken. Schedule 40 PVC pipes, with thinner walls and increased likelihood of failure at low temperatures, are especially prone to this.

High temperatures help PVC to soften and increase its flexibility. Under pressure especially, this might cause the pipe to droop or bend.

Particularly in cases where temperatures will vary significantly, it is imperative to take operating temperature range into account while choosing PVC pipes.

Expected Lifespan and Durability, Schedule 40 pvc vs schedule 80 pvc

Especially in places where they are not exposed to strong UV radiation or extreme temperatures, PVC pipes are well-known for their long life and resilience.

Often with its larger walls, Schedule 80 PVC pipes have a longer lifetime than Schedule 40 PVC pipes. Their greater resistance to wear and tear makes them perfect for uses calling for long-term performance.

Though less durable than Schedule 80 PVC pipes, Schedule 40 PVC pipes remain a good choice for many uses, especially in mild pressure and temperature requirements. Furthermore less expensive than Schedule 80 PVC pipes are they.

The quality of the pipe, the installation techniques, and the climate all affect PVC pipe lifetime.

Cost and Availability

Making a purchase involves much thought on PVC pipe pricing. Prices vary based on the size and length of the available Schedule 40 and Schedule 80 PVC pipes. Making wise judgments depends on an awareness of the elements affecting the availability and pricing of these pipes in different locations.

Cost Comparison

Factors like pipe diameter, length, and manufacturer define Schedule 40 and Schedule 80 PVC pipe costs. Schedule 80 PVC pipes cost more generally than Schedule 40 PVC pipes.

This is so because larger walls of Schedule 80 PVC pipes increase their durability and resistance to higher pressures. The length and size of the pipe will determine the range of cost difference—between 10% and 30%.

Factors Influencing Cost

Several elements influence the general cost of PVC pipes:

Raw Material Costs: Worldwide market circumstances and demand affect the price of PVC resin, the main raw material used in PVC pipe fabrication.

Extrusion, cutting, and packaging are among the various operations involved in the production process that ultimately affect the cost.

Transportation Costs: Depending on the distance and mode of transportation, carrying PVC pipes from the manufacturing facility to the distribution center and lastly to the end user costs different.

Demand: Supply and Demand: Increased demand for PVC pipes could translate into more expensive costs. On the other hand, smaller demand can lead to lower prices.

The pricing in the PVC pipe market may also be influenced by the degree of competitiveness. While a less competitive market might allow for higher costs, a very competitive market could lead to reduced prices.

Availability

Along with the pipe’s size and length, region affects the availability of Schedule 40 and Schedule 80 PVC pipes. Most nations have both kinds of PVC pipes readily available; big manufacturers keep vast distribution networks.

Still, things like availability can be affected by:

Local Demand: Areas high in PVC pipe demand could have more choices than those with low demand.

Distribution networks of manufacturers might affect the availability of pipes in different locations by means of their extent and efficiency.

Seasonal Factors: Demand for PVC pipes changes with the seasons; increased demand during peak building seasons could cause brief shortages.

Natural disasters like earthquakes and hurricanes can cut off supplies and restrict the availability of PVC pipes in impacted areas.

Installation and Maintenance

Like building a beautiful Balinese temple, installing PVC pipes calls for accuracy, attention, and some knowledge. Whether you choose Schedule 40 or Schedule 80, the approach is the same; yet, there are some minor differences that indicate one choice would be more appropriate for particular activities.

Installation Procedures

Although building a strong and durable system depends on the correct procedures, installing PVC pipes is a straightforward task. The main steps are broken out here.

First and most importantly, you need a well-defined plan. Planning and preparation Calculate the area, map the pipe path, and get all needed supplies. This covers PVC pipes, fittings, glue, and any cutting and joining tool utilized.

Cutting and Joining: PVC pipes call for a specialist saw. To get a close fit, make sure your cuts are square and clean. Most often utilized joining material is PVC cement. After lightly laying some cement on the pipe and the fitting, firmly press them together.

Before exerting joint pressure, let the cement completely set.

Enough support is needed of PVC pipes to prevent drooping and leaks. The application will dictate whether you employ hangers, clamps, or braces. Tightly fasteners the pipes to the supports will provide a strong system.

Testing and inspection of the system for leaks is crucial following installation. Pressurizing the system with water and then looking for leaks at the fittings and joints will help to do this.

Ease of Installation

Although both Schedule 40 and Schedule 80 PVC pipes are usually easy to install, their usability varies somewhat. Th thinner walls of Schedule 40 PVC pipes make cutting and joining simpler.

For jobs requiring simple installation, they are therefore a great option. Conversely, schedule 80 PVC pipes are appropriate for uses needing high pressure or impact resistance since they are harder and more durable.

Maintenance and Inspection

Safety and lifetime depend on your PVC pipe system being maintained. Frequent inspections help to identify any early on issues, so preventing expensive repairs. These are some key maintenance pointers:

Regular visual inspections throughout the system should reveal evidence of leaks, corrosion, or damage. Search for pipe or fitting cracks, holes, and discoloration.

Joint Inspection: Give the most careful attention to the most susceptible parts of the system: joints. Search for any proof of separating or leaking.

Pressure testing involves routinely looking for leaks in the system using a pressure gauge. This will help to identify any problems that might not be clear-cut from a visual examination.

Should you be using the system for water distribution, ensure that it is routinely cleaned and flushed to remove any collected silt or trash.